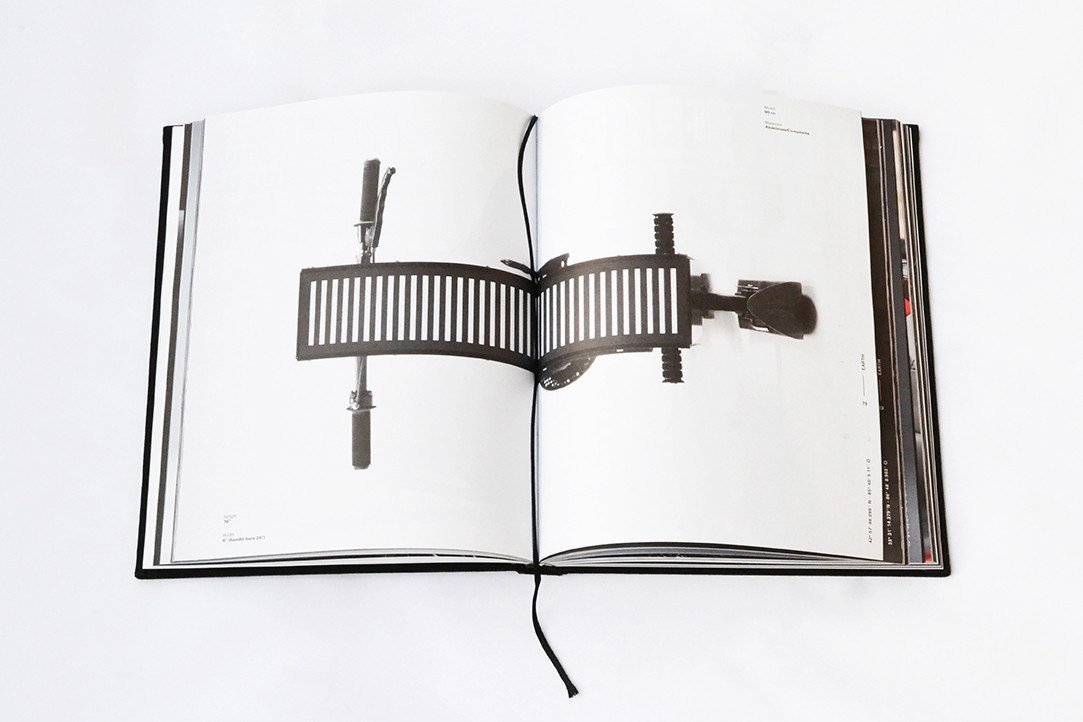

Dab Motors has always surprised us with their builds. Instead of opting for traditional custom motorcycle building, Simon Dabadie uses the latest technology to create his pieces.

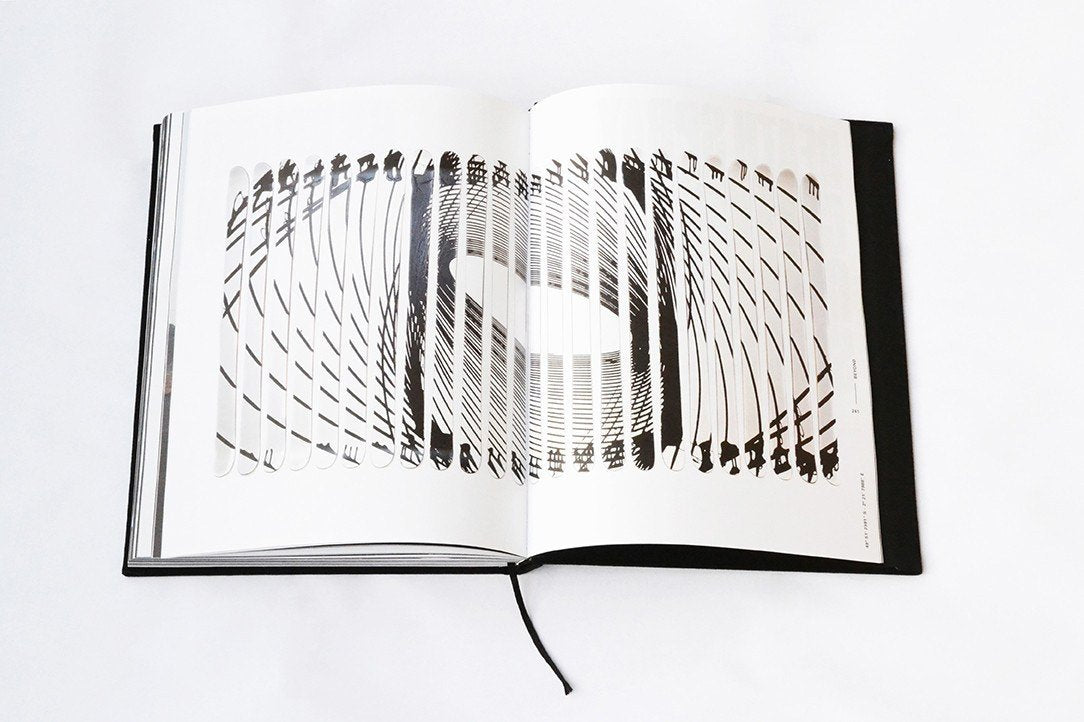

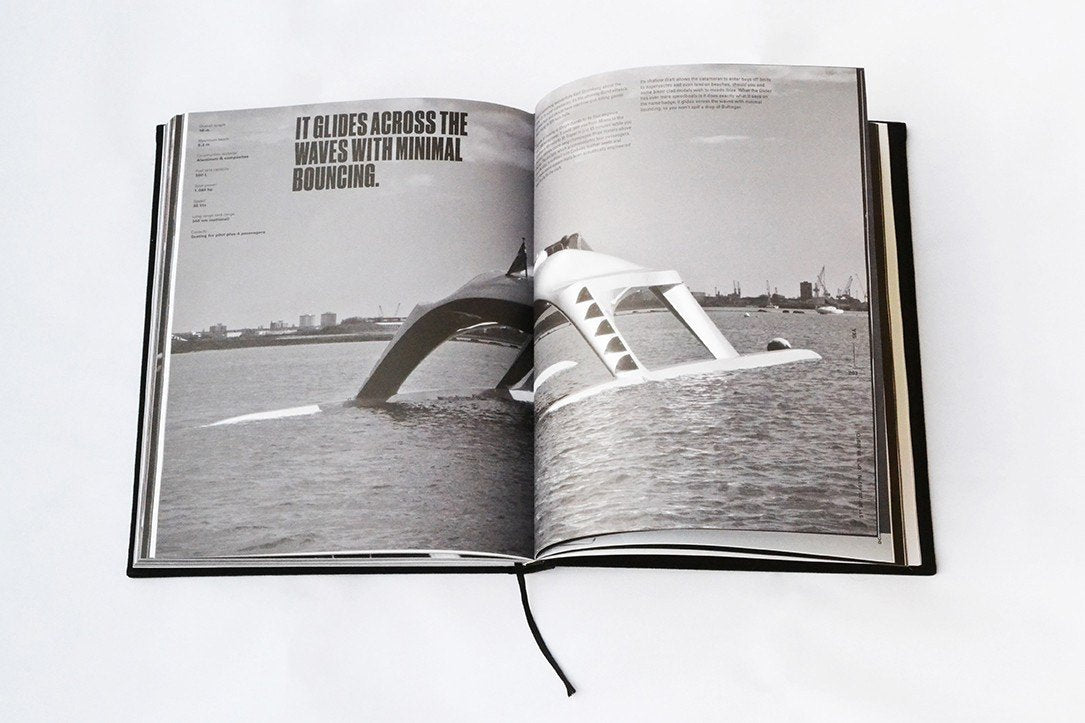

The "Alter" XSR900 commissioned by Yamaha Yard Built is a prime example of Dabadie's constant search to push technology forward in motorcycle building. Having experience in motorcycling, design and engineering, Simon put all of his skills together to create a unique motorcycle with a unique process. In collaboration with Poly-Shape, Dab Design was able to 3D print the pieces of the motorcycle thanks to class leading laser beam melting. Poly-Shape manufactured the headlight bracket, top triple tree, subframe and the handlebar risers. They were sculpted after a 3D scanned model of the motorcycle. Thanks to the printing technology, the frame snaps right on the motorcycle and features a unique shape that would be nearly impossible to create by hand.

The bodywork of the motorcycle is built from ampliTex flax fibers. Simon says that flax fiber has many natural properties like translucency, great looks and even good mechanical properties. In collaboration with Compositadour Research, a KUKA robot carefully machined the molds out. The body was then shaped layer by layer of fiber, held together by epoxy resin and then shaped to become the shell of this beautiful motorcycle. The flax fiber allows us to take a peak at the beautiful LED headlight hidden underneath which forms a square of light for day use. A powerful projector in the center creates more than enough light for it to be used during the night as well.

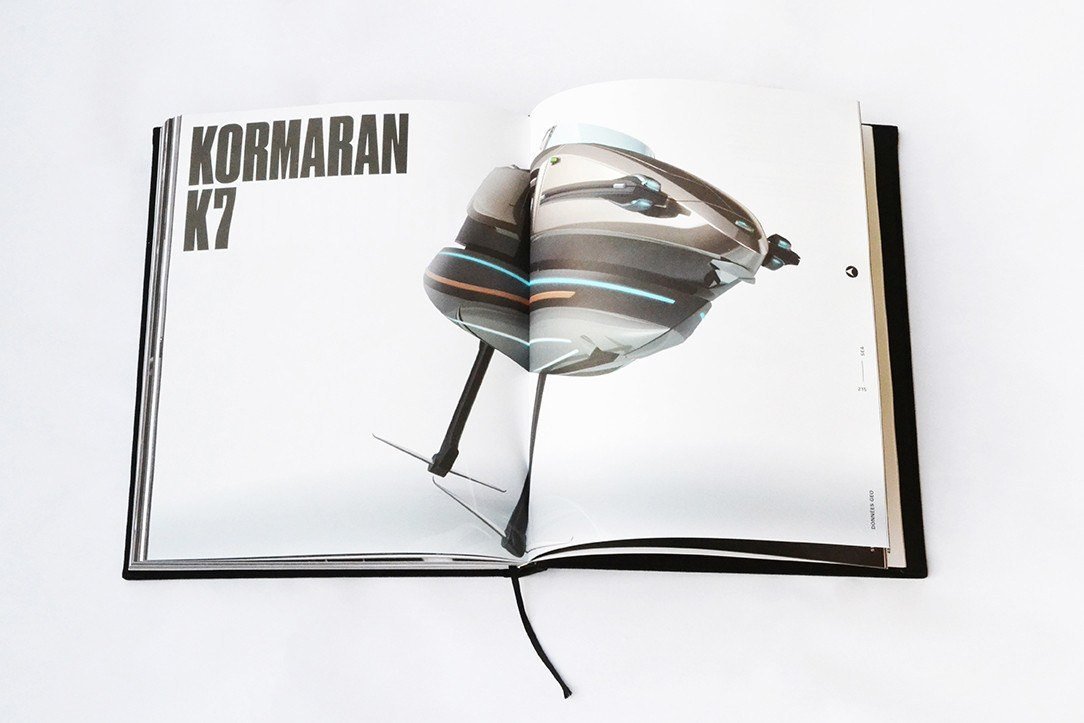

Simon took care of every detail of the bike so he installed an Arduino micro-controller that can link to your iPhone via Bluetooth, giving you full control over the LED lighting of the bike. Performance bits have not gone untouched either, with Öhlins Suspensions on both sides, Rotobox RBX2 carbon wheels, Brembo brakes and Michelin Road 5s tires. A DNA performance filter was installed together with an IXIL SX1 exhaust. Rizoma is the manufacturer of choice for all the little bits like bars, mirrors, grips, brake reservoirs and gas caps. Gilles Tooling took care of the rear sets. Simon kept the stock speedo but moved it flat to the tank cover. The seat has been upholstered in Armalith - an abrasion resistant fabric that is also used on Simon's clothes in the pictures. The jeans and vest are custom made for him by Bolid'Ster. Qwart Helmets brought in a custom one-off Phoenix helmet for the bike and Velomacchi delivered their Speedway pack and gloves.

Taken care of in every little detail, "ALTER" serves as a playground for builders to see that the world of custom motorcycles is turning towards technology. While handbuilt motorcycles retain a special value, the ease of producing customs with 3D printing technologies, sustainable materials and high-technology parts might bring the rise of 3D printed customs. What is your opinion on this technology being applied to custom bike building?

Images courtesy of BikeEXIF